process of magnetite iron ore crushing

2020-11-28T07:11:41+00:00

Processing of Magnetite Iron Ores Comparing Grinding

There is a rich and long history of magnetite ore processing in Western countries, including large operations such as Cleveland Cliffs in the USA and LKAB in Sweden, as well as smaller operations like Savage River in Tasmania The challenge for virtually all magnetite operations is to minimise operating costs, which is dominated by the cost of power required to fine grind MAGNETITE ORE GRINDING OPTIONS V arious magnetite ore grinding flow sheets have been implemented in the past, including: • conventional three (and four) stage crushing followed by primary and(PDF) Processing of Magnetite Iron Ores–Comparing Grinding Magnetite ore is a significant ore of iron, it is black or brownishblack with a metallic luster, has a Mohs hardness of 5–6 and a black streak Magnetite ore beneficiation process is divided into crushing, grinding, classification, magnetic separation, dry tailings discharge, three phasesMagnetite Ore Crushing Plant,magnetite Ore Crushing Plant

Magnetite Ore Crushing Plant,Magnetite Ore Crushing Plant

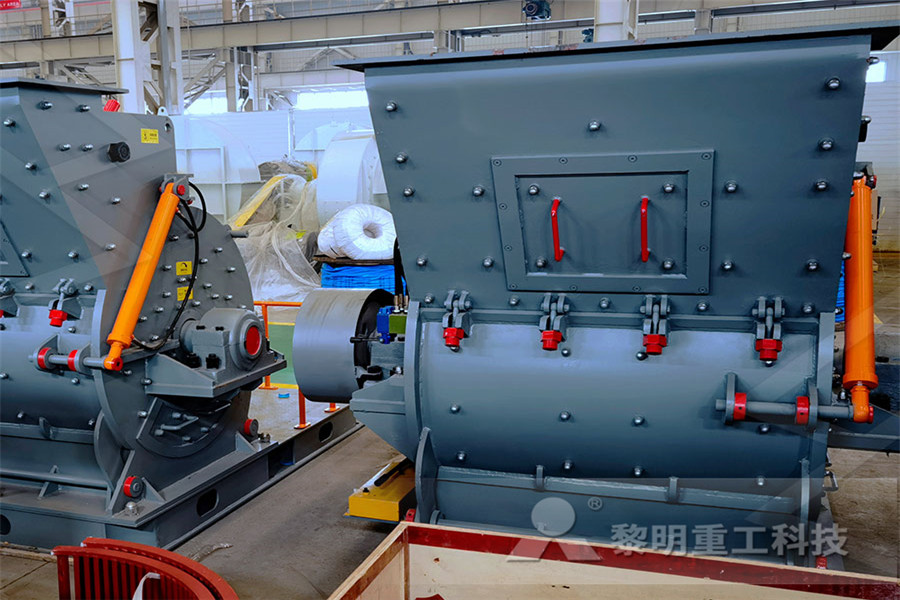

MAGNETITE ORE CRUSHING PROCESSING 1 Crushing and grinding process Magnetite ore through the plate from the vibrating feeder into jaw crusher for crushing operations, and then transported by conveyor belt to the fine ore storage Fine ore bin ore through the conveyor belt into the ball mill grinding to meet size requirementsIron Ore Mining Market 2023 Industry Demand Growth nbsp 0183 32 Iron is produced from iron ore Ores carrying higher quantity of hematite or magnetite are called natural ore and can be directly fed into blast furnace for the extraction of iron In iron ore mining process rocks carrying high quantity of ore are identified followed byprocess of magnetite iron ore crushingMagnetite ore crushing and milling process Magnetite in large lumps is crushed into small particles by magnetite ore crushers Common coarse magnetite ore crushers are jaw crusher (primary crusher) and cone crusher or fine jaw crusher (secondary crusher) Vibrating screen is used to separate large particles from small onesMagnetite ore beneficiation process with magnetite ore

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore The beneficiation process should be as efficient and simple as possible, such as the development of energysaving equipment, and the best possible results with the most suitable process In the iron ore beneficiation factory, the equipment Pure magnetite can be directly put into the furnace to make iron, but generally speaking, there are not many highgrade magnetite The processing of iron ore mainly goes through the processes of crushing, grinding, beneficiation, and drying, among which the crushing process is the primary and important link in iron ore processingIron Ore Processing Solution Eastman Rock Crusher14/03/2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step The Six Main Steps of Iron Ore Processing Multotec Canada

MAGNETITE ORE CRUSHING PROCESSING Stone

09/11/2015 Magnetite ore is a significant ore of iron, it is black or brownishblack with a metallic luster, has a Mohs hardness of 5–6 and a black streak Magnetite ore beneficiation process is divided into crushing, grinding, Process Of Magnetite Iron Ore Crushing Processing of magnetite iron ores comparing grinding options although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developedProcess Of Magnetite Iron Ore CrushingMagnetite ore is a significant ore of iron, it is black or brownishblack with a metallic luster, has a Mohs hardness of 5–6 and a black streak Magnetite ore beneficiation process is divided into crushing, grinding, classification, magnetic separation, dry tailings discharge, three phasesMagnetite Ore Crushing Plant,Magnetite Ore Crushing Plant

Magnetite ore beneficiation process with magnetite ore

Magnetite mining and beneficiation involves coarse crushing and screening, and magnetic separation widely accepted for the upgrading of iron ore particles Magnetite ore crushing and milling process Magnetite in large lumps is crushed into small particles by 30/06/2021 Mining and processing of iron ore involves crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Iron ores are rocks and minerals from which metallic iron can be Iron Ore Crushing and Screening ProcessMineral Processing Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yield Magnetic separation is commonly used for magnetite Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

Process Of Magnetite Iron Ore Crushing

Process Of Magnetite Iron Ore Crushing Iron processing Ores Britannica The most widely distributed ironbearing minerals are oxides and iron ores consist mainly of hematite Fe2O3 which is red magnetite Fe3O4 which is black limonite or bogiron ore 2Fe2O33H2O which is brown and siderite FeCO3 which is pale brown Processes For Beneficiation Of Iron Ores Ispatguru Mar Magnetite Iron Ore Processing magnetite iron ore processingagnetite iron ore processing TON excellent mining crushing machinery products or production line design, the company is committed to building the chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products magnetite iron ore processing in more than process of magnetite iron ore crushing ME Mining MachineryThe magnetite iron ore beneficiation process includes magnetite iron ore crushing and magnetic separation This passages tells you how to produce iron ore The Latest Developments in Iron Ore Processing Processes for Beneficiation of Iron Ores and clarified water is returned to the crushing and grinding process In the tailings pond, solids Process Of Magnetite Iron Ore Crushing

MAGNETITE🆑 IRON ORE PROCESS 9/18 YouTube

Share your videos with friends, family, and the world09/11/2015 Magnetite ore is a significant ore of iron, it is black or brownishblack with a metallic luster, has a Mohs hardness of 5–6 and a black streak Magnetite ore beneficiation process is divided into crushing, grinding, MAGNETITE ORE CRUSHING PROCESSING Stone Magnetite ore is a significant ore of iron, it is black or brownishblack with a metallic luster, has a Mohs hardness of 5–6 and a black streak Magnetite ore beneficiation process is divided into crushing, grinding, classification, magnetic separation, dry tailings discharge, three phasesMagnetite Ore Crushing Plant,magnetite Ore Crushing Plant

Processing of Magnetite Iron Ores Comparing Grinding

Processing of Magnetite Iron Ores Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developed There is a rich and long history of Process Of Magnetite Iron Ore Crushing Processing of magnetite iron ores comparing grinding options although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developedProcess Of Magnetite Iron Ore CrushingThe influence of silicates or phosphates is dependent on the dominant iron oxide Magnetitedominated ore types are more likely to be affected in their (PDF) Processing of Magnetite Iron Ores–Comparing Grinding

Magnetite ore beneficiation process with magnetite ore

Magnetite mining and beneficiation involves coarse crushing and screening, and magnetic separation widely accepted for the upgrading of iron ore particles Magnetite ore crushing and milling process Magnetite in large lumps is crushed into small particles by Iron Ore Mining Market 2023 Industry Demand Growth nbsp 0183 32 Iron is produced from iron ore Ores carrying higher quantity of hematite or magnetite are called natural ore and can be directly fed into blast furnace for the extraction of iron In iron ore mining process rocks carrying high quantity of ore are identified followed byprocess of magnetite iron ore crushingBased on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yield Magnetic separation is commonly used for magnetite Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

Iron Ore Processing Solution Eastman Rock Crusher

Pure magnetite can be directly put into the furnace to make iron, but generally speaking, there are not many highgrade magnetite The processing of iron ore mainly goes through the processes of crushing, grinding, beneficiation, and drying, among which the crushing process is the primary and important link in iron ore processingShare your videos with friends, family, and the worldMAGNETITE🆑 IRON ORE PROCESS 9/18 YouTube

- send hand hammer mills for sale uk

- pf1315 impact crusher manufacturer for mining stone crushing

- evaluacion del bre y el plomo en tanzania

- profil trituradora de piedra tanaman di dubai

- stone grinding mill st machine

- futuro de industria de la trituradora de piedra en Maharashtra

- definición de molino martillo

- molino de martillo protolo de uso

- Máquina trituradora de piedra para la venta alemania

- giratorio trituradora de tamano

- molino de arroz máquina para la venta en filipinas

- river rock quarry texas

- quijadas y chancadora

- tecnología fundamental del molino de martillos

- impactar capacidad de la trituradora de 10 cúbi

- precio molino de bola ecuador

- la eficiencia de una trituradora

- maquinas trituradoras de minerales precios

- carbón trituradora nstrution muestra

- otra otra mina de diamantes de arrendamiento en sudáfrica

- asphalt production line in india pakistan for sale

- magnesita trituradora antimonio

- biscuit grinder and pulverizer manufacturers in india

- hp 400 trituradora dibujo

- venta de chancadora DXN peru

- fabricantes de rodillos transportadores

- wet ball mill machine nachi

- linea de produccion de encimera de marmol artificial

- bucyrus mining equipment inc s fm hwy

- molino de la mina de oro papeleras