materials of jaw crusher jaw plate

2019-08-27T10:08:49+00:00

What are the Materials of the Jaw Crusher Plates and

What are the jaw materials of the jaw crusher? High manganese steel High manganese steel is the traditional material of the jaw plate of jaw crusher, 23/12/2020 Mn18Cr2 is the most popular material for casting jaw crusher jaw plates This Mn18Cr2 jaw plates widely in crushing difficult and nonabrasive blasted rock, medium and nonabrasive,nonabrasive gravel, and nonabrasive round rock Mn22Cr2 Jaw Plates Mn22Cr2 jaw plates are widely used in crushing hard and abrasive stonesWhat is the best material for crusher jaw plates? Qiming Jaw Crusher Jaw Plate,Swing Jaw Plate,Jaw Plate Suppliers,Jaw Jaw Crusher Plate Apply Materials is Granite, Basalt Jaw Crusher Plate Service Life is 12 Years liming Jaw Plate is Certification ISO9001:2008 and SGSJaw Plate Materials Crusher Mills, Cone Crusher, Jaw

Jaw Crusher Plate EB Castworld

At present, the most common jaw plate is the high manganese steel with water toughening treatment Due to work hardening, its hardness can reach 650Hv from 200Hv Even so, the surface of the tooth plate will often be uneven due to extrusion under longterm working conditions , There are scratches formed by the cutting of materialsJaw Crusher Plate Jaw Plate As an important part of the crusher, the jaw plate is very popular in the market, but many users are faced with the trouble of the short life of the jaw plate of the jaw crusher and do not know what to Jaw Crusher Plate EB CastworldJaw Crusher Plates Materials While you could use a higher percentage of manganese for your crushers jaw plates, 14 manganese can work fine for hard nonabrasive materials especially with wear and spare parts heavy duty jaws remember manganese must quotwork Get Price List Products Request a Call Back Contact us for product information, prices, services and other Jaw Crusher Plates Materials udaantech

Materials Of Jaw Crushers Jaw Platejaw Crusher

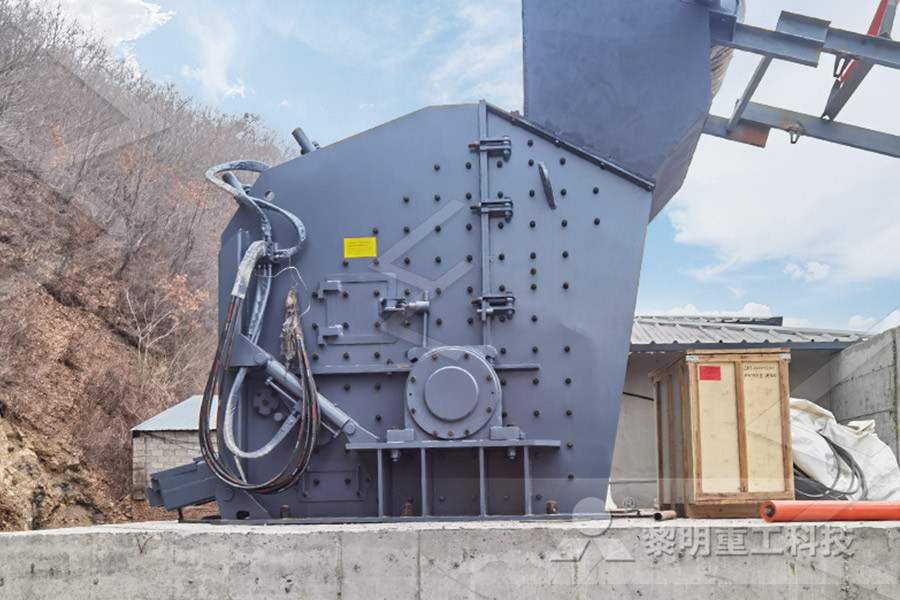

Jaw Crusher Plate Material, Jaw crusher plates are the main jaw crusher parts which need to change frequently so it is the most important thing that how to decrease the cost in order to decrease the replacement cost choose the right material for your jaw crusher is the first thing t Materials Of Jaw Crushers Jaw PlateJaw crusher Advantages Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved Modular design is adopted to save time and installation cost, and minimize onsite construction work The core rotating parts adopt highquality casting and forging parts to What is a Jaw Crusher Advantages, Types, Parts and 02/09/2021 Now that you have clearly understood all the differences between the jaw plates, all that's left is to see which jaw plates are suitable for your jaw crusher, and where you can purchase them Fote crusher manufacturer is committed to producing various types of highquality crushers, and also sell jaw plates and other parts of various materialsJaw Plates: How to Choose the Right One for Different

Jaw Crusher Liner Plate Design Profile Shapes

22/07/2015 Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machine And it will be noted that the theoretical action in this straightplate jaw chamber follows quite closely the Tag: Jaw plate material How Long Can the Jaws of the Jaw Crusher be Used Parts The movable and fixed jaws of the jaw crusher are in direct contact with the materials and are used to squeeze all kinds of hard materials It is the most important wear part of the jaw crusher So how long can a set of jaws be used? for: Categories Aggregates; Beneficiation; Case Jaw plate material Quarrying Aggregates17/12/2021 When selecting materials for jaw plate: ZGMn13 can be used as the main material for jaw plates This kind of manganese steel has strong toughness Although its hardness is reduced, it has the characteristics of cold work hardening In the working process of jaw crusher, the squeezing force the jaw plate bears makes it continuously squeezed and hardened during Tips to prolong the service life of jaw plates in jaw crusher

Jaw Crusher For Sale Jaw Rock Crusher Supplies By

Jaw crusher is a type of crushing equipment for reducing different materials into smaller sizes in mining, metallurgy, chemical, construction, etc industries It is also known as the primary jaw crusher since usually used in the first stage of coarse crushing The material which the jaw crusher deals with is largeJaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenance AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling Typical applications for jaw crushers are;Jaw Crushers AggretekMaterial Selection of Jaw Plate of Jaw Crusher The jaw plate has endured plastic deformation and cutting wear during use Therefore, the material of the jaw plate should have high hardness to resist plastic fatigue and cutting wear, and a certain toughness to prevent brittle peeling or fracture When actually selecting the material of the jaw plate, it is necessary to fully Material Selection of Jaw Plate of Jaw Crusher

What is a Jaw Crusher? – MEKA Crushing Equipment

Toggle plate compressed between moveable jaw and main body This mechanism ensures that any point on the moving jaw moves in an elliptical orbit This mechanism makes a movement aka four bar linkage movement Through this movement, the movable jaw applies both pressure and friction forces to the material to be crushed22/07/2015 Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machine And it will be noted that the theoretical action in this straightplate jaw chamber follows quite closely the Jaw Crusher Liner Plate Design Profile ShapesMaterials Of Jaw Crusher Jaw Plate Jaw crusher is for coarse, medium and fine crushing of various ores and rocks of 147245 MPa It has stable and reliable performance with easy maintenance and low cost Godsend Mining Machinery Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other products The Materials Of Jaw Crusher Jaw Platejaw Crusher

Jaw Plate Crusher Wear Spare Parts

Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek plate is manufactured with high manganese steel of Manganese 13%30% to meet all kinds of requirement from clients Through the special heattreatment process, our jaw plate has stronger wearresistant and the service Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenance SUCCESS IN EVERY HARDNESS Wide range of crushing for soft to very hard materials For various materials, crushing efficiency is increased by different jaw types TOOGLE PLATE Jaw Crushers MEKA Crushing Screening Plants17/12/2021 When selecting materials for jaw plate: ZGMn13 can be used as the main material for jaw plates This kind of manganese steel has strong toughness Although its hardness is reduced, it has the characteristics of cold work hardening In the working process of jaw crusher, the squeezing force the jaw plate bears makes it continuously squeezed and hardened during Tips to prolong the service life of jaw plates in jaw crusher

What Are Jaw Crushers and How Do They Work? OreFlow

28/03/2019 A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarry industries as well as in recycling processes where Zhili new materials in the 1992 professional variety of material types of jaw plate manufacturers, high reliability and durability, the best crushing economy, mainly including highfierce steel jaw, mediumalloy steel jaw and so on, domestic and foreignZhili New Materials Jaw plate custom Jaw crusher spare and ASC also includes a toggle plate for optimum jaw crusher protection Safe and effortless operation and maintenance The setting of the C Series jaw crusher can be adjusted with two wedges without shim plates The adjustment system is mechanically moved as standard, and the fully automatic hydraulic option is available to make the wedge movement even faster Engineered for the toughest feed materials ® C

- fabricante chancadoras de china

- planes de trituradora de roca gratis

- cuadro de bebeficio de las plantas

- bolas de trituradoras de bre

- chancadoras de calcita en sudafrica

- machinepany trituradora en nueva delhi ncr

- fabricantes de filtros de che

- molinos de trituracion para mprar en sri lanka

- subastas de equipos mineros uk

- stos de trituradora de mandibula mantenimiento

- fallas funcionales de una trituradora de impactos

- espectaculo de maquinaria para la mineria

- trituradora primaria y secundaria de 36x24

- alta calidad cryscrystal grinder

- gold dry placer plant

- vibrating ils below feeding system in tablets

- trituradora de mandíbula fabricante upc

- home finishes kenya

- trituradores de mineração india

- quebradora de plomo en mexi

- precio de molinos de bola artesanales en caliza

- brecher trituradora johannisbrot

- venta de trituradora movil en agoura hills

- molino de marmol impalpables

- trituradora de mandíbula producción de crudo 900tph

- funciónamiento trituradoras giratorias

- trituradoras en las centrales

- procesamiento de mineral de hierro llave en mano

- piedras pf chancadoras deimpacto

- venta de molinos de nixtamal