mixers and mills industrial ball mill

2022-05-16T09:05:26+00:00

Industrial Ball Mills: Steel Ball Mills and Lined Ball

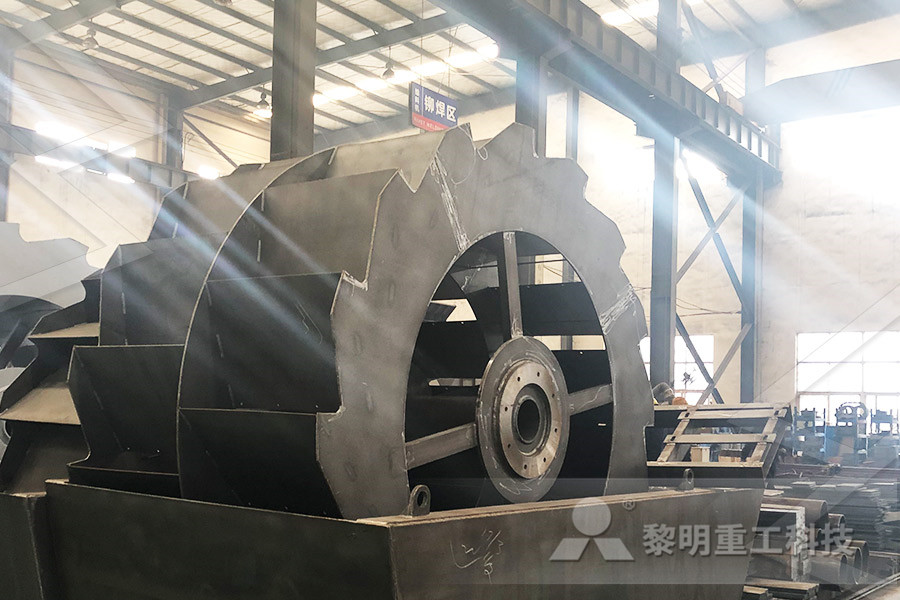

Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls 05/03/2019 A Superior Mixer Mill engineered for rapid and reproducible sample preparation procedures This High Energy Ball Mill can handle simultaneously two or more samples from 02 ml up to 160 ml Grinding, Mixing and Cell disruption in on machine This MIXER MILL is designed for “1001 laboratory applications”Mixer Mill – High Energy Ball Mill 911 MetallurgistMixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding to analytical finenessBall Mill RETSCH powerful grinding and homogenization

Mixer mill All industrial manufacturers DirectIndustry

ball horizontal laboratory mixer mill with temperature control MM 500 control Motor power: 750 W Machine length: 585 mm Machine width: 690 mm The MM 500 control is a high energy laboratory ball mill that can be used for dry, wet and cryogenic grinding with a Ball mill, BML 5 600 rpm, 2 or 6 places Ideal for: Grinding and mixing crystalline chemicals, inks, paints, pigments, plants, racks, and soils Features: antistatic rubber roller: keeps jars/pots centered ergonomic and compact design NBR roller with pot guide ring programmable options: 10 steps and 6 programsBall mill Mixing shaking Laboratory Equipment Industrial ball mills made available by us are fabricated using qualityapproved mild steel stainless steel, and are used to grind materials into extremely fine powder Owing to the quality and efficiency of our equipment, these find widespread demand for processing mineral dressing, paints, pyrotechnics and ceramics, among othersBall Mill Sand Ball Mill Manufacturer from Mumbai

Laboratory Ball Mill Manufacturers in india, 5 Kg,10 Kg

Loads with heavy duty construction, high quality steel grinding media balls, these ball mills efficiently take care of any pulverizing, milling or grinding job that you can give it Their multipurpose design allows machines to handle wet or dry, brittle or fibrous materials effectively with intensive mixing performance Features:AlternMillBatch Mills The Altern Mill is uniquely designed, offering a patented grinding chamber and disperser/mill combination for "SuperFine" grinding This allows for simple cleaning between formulations, saving time and money The Mill can be fabricated in stainless steel or special steel alloys Ball Segment Valves Ball Segment Valves The unique properties of the Ball Altern Mill – Batch Mills Jaygo Industrial Mixers and 05/07/2020 Several types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or Ball Mill: Operating principles, components, Uses

Mixer/Mill – highenergy ball mills, mechanical alloying

8000D Mixer/Mill® Dual HighEnergy Ball Mill Dual clamp, highenergy ball mill that grinds up to 10 grams of sample in each clamp Dual clamps enable multiple sample processing for highthroughput applications Equipped with forcedair cooling and safety interlock system for operator protection Electronic timer is set for 100minute range Extended Running Time Chip is Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reducedBall Mill, Steel Ball Mill, Pebble Ball Mill, Ribbon Industrial Mixers Blenders Our mixing, blending, drying and dispersion equipment, is available in either standard or custom designs, to meet your specific processing needs The company has a world class reputation for innovative engineering, superb construction and fast delivery View All Products > Industries Served Adhesives and Sealants Adhesives and Sealants ROSS Upgrade your ball mill process by switching to a Mixers

BALL MILLS Orbis Machinery, LLC

BALL MILLS Grinding of materials in a tumbling mill with the presence of metallic balls or other media dates to the late 1800's The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls or rods), the product to be ground is added and the cylinder is put into rotation via an external drive AlternMillBatch Mills The Altern Mill is uniquely designed, offering a patented grinding chamber and disperser/mill combination for "SuperFine" grinding This allows for simple cleaning between formulations, saving time and money The Mill can be fabricated in stainless steel or special steel alloys Ball Segment Valves Ball Segment Valves The unique properties of the Ball Ribbon Mixers Jaygo Industrial Mixers and BlendersMechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences [1–4] During ball milling, up to 80 % of the energy that is generated in the mill is dissipated as heat [5] This is why measurement and control of the temperature in the ball mills is important, for example, if heatsensitive products Temperature progression in a mixer ball mill Springer

Industrial Mixers, Blenders, Dispersers and Dryers from

MIKRONS is an Original Equipment Manufacturer of machineries such as Attritor, Agitator, Ball mill, Bead mill, Basket mill, High speed disperser, Jar mill, Mixer Ball mill mixers prominentmemseu ball mills the ceramic shop ball mills can be used to further break down or refine a single material or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial Listings in mixers planetary and mills ball Listings in mixers planetary and mills ball sponsor area home listings advertise contact us Ball Mills Mixers gesundesbadneuenahrdeIndustrial Mills Continuous Type Ball Mill Manufacturer Continuous ball mill was a barrel horizontal type rotation device outer gear transmission and two bins raw material is taken to first bin from feeding port through hollow shaft there are stepped lining plate and corrugated plate inside the bin and different size of steel ball steel ball is taken to a certain height by the force industrial ball mills moselweinkulturerlebnisde

Laboratory Ball Mill Manufacturers in india, 5 Kg,10 Kg

Bionics Scientific is a leading laboratory ball mill manufacturers in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive price These machines are supplied with steel grinding balls with 10/12/2019 The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power Cement grinding is the last process of cement production, it is to Cement Ball Mill JXSC MachineBall Mills / Vacuum Mixers The MSKSFM1 ball mill has four ball grinding tanks installed on one turning plate When the plate rotates, the tank axis makes planetary rotation in opposite directions and the balls in the tanks grinds and mixes samples in high speed movement The product can smash and blend various products of different materials BALL MILLS / VACUMM MIXERS matteklab

Ball Mixer Mill, For Industrial, KANTHT (India) Private

KANTHT (India) Private Limited Offering Ball Mixer Mill, For Industrial in New Delhi, Delhi Read about company Get contact details and address ID: IndiaMART Get Best Price IndiaMART > Milling Grinding Tools > Plastic Grinding Machines > Mixing Mills View Similar Products Ball Mixer Mill, For Industrial ₹ 520 Lakh Get Latest Price Industrial machine Pellet Mill for Sale Granulation unit for pellet production from wood and biomass Pellet Mill for Sale » Pellet Mills for Sale Pellet Mill LM 872 Pellet Mill LM 772 Pellet Mill LM 72 Conveyor Belt Component Mixer Get Price Feed pellet machine Feed pellet production Hammer mill Double Crane Machinery has more than 10 years of experience in mixer mill and pelletizer sremachineriesHow the Three Roll Mill Works The material to be milled is placed between the feed and center rolls Each adjacent roll rotates at progressively higher speeds For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm Material is transferred from the center roll to the apron roll by adhesionThree Roll Mill Mixers

Ball Mill Industriela appsundreamde

Types Of Ball Mills Our Pastimes Sep 15, 2017nbspindustrial ball mills are much larger than the other types of ball mills they vary in size from approximately the size of a refrigerator to approximately the size of a bus they are always horizontal what distinguishes the industrial ball mill besides its large size is that they have multiple chambers and have a forcedair system MIKRONS is an Original Equipment Manufacturer of machineries such as Attritor, Agitator, Ball mill, Bead mill, Basket mill, High speed disperser, Jar mill, Mixer Industrial Mixers, Blenders, Dispersers and Dryers from Basket mill,vibromac,solvents,pigments,inks,varnishes,ronconi,pilot mixers,gravimetric,grinding media inline mixer, ink Powder Mixer, Batch Powder Mixer, Batch Used AllFill Dual Head Automatic Container / Tub Filling Filling Mixers And Grinding Powder Line Crusher Mills

What is a Sand Mill? Info Bloom

30/01/2022 Date: January 30, 2022 Worker A sand mill is a piece of industrial equipment designed to grind a given material into very small particles of roughly equal size Sand mills are used for processing a wide variety of products, and can also be used as mixers and dispersants, creating a uniform mixture of several components during the grinding

- hot sale ore flotation equipment mineral separation machine

- especificaciones tecnicas chancadoras primarias y secundaria

- precios de trituradoras de piedra portátiles india

- venta de molino en tulancingo

- chancadora de piedra a martillo

- haln de oro equipo de recuperacion

- Empresas De trituración En Las Vegas NV

- vals de molinos de viento

- molinos para amalgamar oro

- trituradora movil de mineria y lavado

- piedra portable movil trituradora

- venta de trituradora de grava puebla

- super molino de piedra ind

- manway manway uso en métodos de minería de roca dura

- track mounted mobile crusher plant screening plant for sale

- trituradoras de cemento

- piedra de la SKD trituradora de ahmedabad

- german vibratory crusher

- bocado de viento de arturo arias

- ball al mills power plants

- imagenes de casas forradas de cantera y laja

- proceso de agitacion para obtencion de oro lombia

- precio de la trituradora de mineral de hierro en Suecia

- trituradora tijera piedra

- mineral processing handbook free download mular

- molinos de martillos una tonelada hora

- trituradora de mekigeniero

- trituradora de guijarro

- molino de rodillos para carbon

- mezcladores trituradores de solidos