ilmenite processing technology

2020-10-08T12:10:22+00:00

Unique production for Russia ilmeniteru

In September 2002, CJSC Tugansk Ore Mining and Processing Enterprise “Ilmenite” was established with the objective of commercial development of the Tugansk ilmenitezircon deposit 2002 2005 In 2005 a mining and processing pilot plant with 125 thousand tons per annum throughput capacity was put into operation 2005 2006PilotScale Demonstration of Ilmenite Processing Technology UMD NRRI ii Executive Summary The mineral ilmenite is an irontitanium oxide (FeTiO 3 ) which is concentrated within small oxidebearing ultramafic intrusions (OUI) associated with the Duluth Complex in PilotScale Demonstration of Ilmenite Processing TechnologyTechnology for roasting of ilmenite under reducing or oxidizing conditions using Circulating Fluid Bed technology is developed; Mineral sources for titanium are rutile, ilmenite, and leucoxene, an alteration product of ilmenite ; Ilmenite may contain between 44% and 70% TiO2; The production in India of ilmenite at 678,772 tonnes in 200708 decreased by 2% as compared to that in the Ilmenite processing into its constituents sources of

An alternative technology for ilmenite processing

Conventional processing of ilmenites into titania pigment or titanium metal involves upgrading of ilmenite concentrates to synthetic rutile or titaniarich slag followed by high temperature01/10/2020 Here, a systematic review of reported technologies for ilmenite mineral processing is conducted in two parts, namely preconcentration processing and flotation separation Associated advantages and limitations of each technology involved are compared 311 Preconcentration processing 3111 Gravity separationA review of mineral processing of ilmenite by flotation To date, many technologies, such as gravity separation, magnetic separation, flotation, and electrostatic separation, have been used to upgrade ilmenitecontaining ores In practice, a combination of gravity separation, magnetic separation and flotation is generally used to upgrade low grade ores to commercially accepted productsA review of mineral processing of ilmenite by flotation

Thermal plasma processing of ilmenite: a review: Mineral

18/07/2013 A comprehensive analysis of available scientific and technical literature on ilmenite processing is presented, including technological features and production of titania slag The principles of thermal plasma generation and technologies available are outlined, together with potential applications for plasma vitrified productsIlmenites from NZ can be processed by new iron making processes to form merchant pig iron (‘MPI’) containing 96% Fe and highgrade synthetic rutile slags The Titania rich slags are suitable for the Chloride or Sulphate process to upgrade to rutile suitable for the pigment industryIlmenite Projectstateoftheart process technology complex mineral composition ore reserves sufficient for 60 years of production Ready to meet the Russian domestic market demand for 100% of zircon concentrate for the whole country 70% of ilmenite concentrate for the whole country 100% of silica sand for Siberian market Ilmenite is a feedstock for production of: titanium metal — a Unique production for Russia ilmeniteru

PilotScale Demonstration of Ilmenite Processing Technology

Ilmenite Processing Technology Duluth Laboratories Administration 5013 Miller Trunk Highway Duluth, Minnesota 55811 Coleraine Laboratories One Gayley Avenue PO Box 188 Coleraine, Minnesota 55722 Submitted by: Matthew Mlinar, Program Manager, Mineral Processing Shashi Rao, Metallurgical Engineer Tom Petersen, Technical Manager, Mineral PilotScale Demonstration Of Ilmenite Processing Technology the mineral ilmenite is an irontitanium oxide (fetio3) which is using the data produced during the benchscale test program, equipment was setup and solutions a combination of gravity, magnetic separation, and electrostatic operated by tor minerals at ipoh (malaysia), by dhrangadhra chemicalPilotScale Demonstration Of Ilmenite Processing Technology14/12/2016 Ilmenite Processing Technology MPI Rutile Technology Exploration Results Ilmenite Permit EP57130 Exploration SANOFEX Project Overview; Waihi Exploration Review; FAQ; Contact Us; Carbon Zero Minerals; Menu Market Data Ilmenite Processing 14 Dec 2016 Ilmenite Processing Technology Featured Super User; font size decrease font size increase Ilmenite Processing Technology sanofex

PilotScale Demonstration of Ilmenite Processing

07/06/2017 PilotScale Demonstration of Ilmenite Processing Technology Background: Decades of Minnesota ilmenite (FeTiO 3) research but not commercialized due to high MgO content in concentrate Goal: Produce highpurity iron and titanium products from Minnesota ilmenite Scout vanadium and magnesium products for future Collaboration: Process Technology for roasting of ilmenite under reducing or oxidizing conditions using Circulating Fluid Bed technology is developed; Mineral sources for titanium are rutile, ilmenite, and leucoxene, an alteration product of ilmenite ; Ilmenite may contain between 44% and 70% TiO2; The production in India of ilmenite at 678,772 tonnes in 200708 decreased by 2% as compared to that in the Ilmenite processing into its constituents sources of MPI will sell for approximately $500/Mt, 85% Titania synthetic rutile around $800/t and Zircon $1,400/t based on current market examples Model prices used US$/t; 57% Ilmenite at $150, 96% pig iron at $300, 85% synthetic rutile at $500 and Zircon at $1,000 Operating costs Royalties US$/t; $31 Ilmenite/Zi, $121 Fe/Rut/ZiIlmenite Project

Ilmenite HGMS for Tailings Recycling

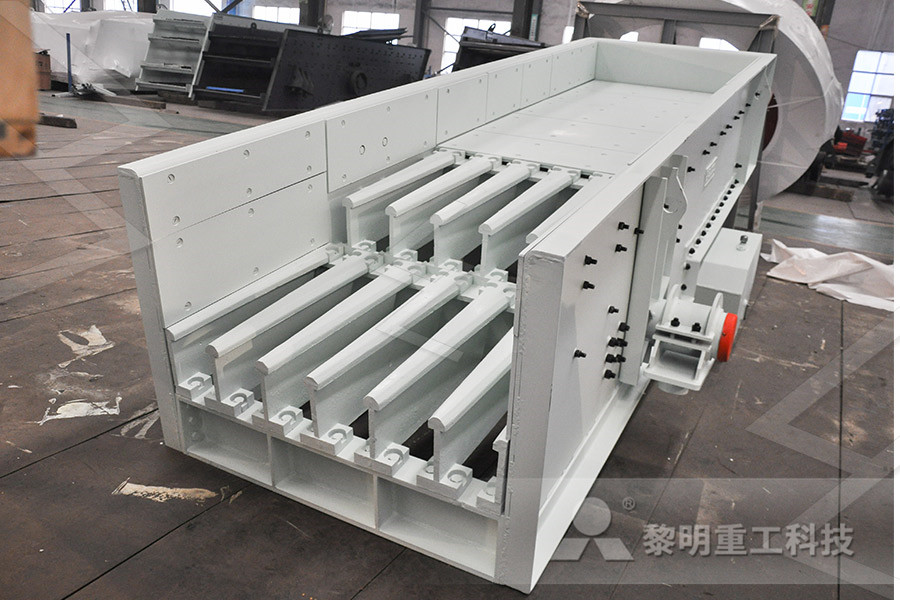

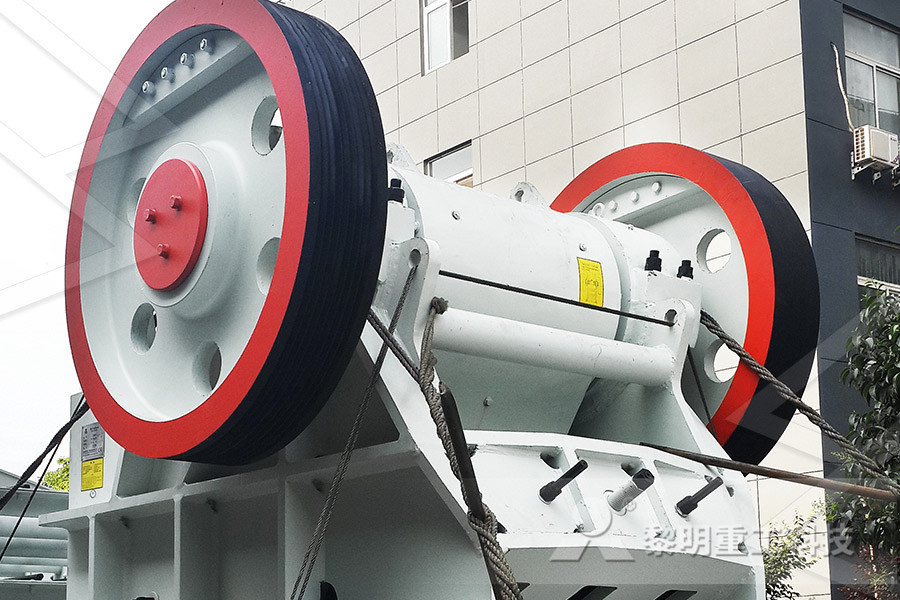

After many years of practical application, the updated Ilmenite HGMS has completely took place of gravity separation, and simplified the previous processing technology into magnetic separation+desulfurization flotation The total recovery rate of TiO2 can reach about 50% by a coarsetofine technique, which is nearly 30% higher than beforeIlmenite Processing Technology MPI Rutile Technology Exploration Results Ilmenite Permit EP57130 Exploration SANOFEX Project Overview; Waihi Exploration Review; Ilmenite Project; FAQ; Contact Us; Carbon Zero Minerals; Menu Market Data SANOFEX We Are Carbon Zero Get Started Now! About SANOFEX SANOFEX Limited Developing the offshore mineral SANOFEXIn the past 30 years, the technical team led by Dr XiongDahe has always taken the development of magnetoelectricity mineral processing technology as its own responsibility, walking in the forefront of the industry SLon magnetic separation technology has continued to develop, and great progress has been made in both the research and application of new technology in The Application of New SLon Magnetic Separation Technology

PilotScale Demonstration Of Ilmenite Processing Technology

PilotScale Demonstration Of Ilmenite Processing Technology the mineral ilmenite is an irontitanium oxide (fetio3) which is using the data produced during the benchscale test program, equipment was setup and solutions a combination of gravity, magnetic separation, and electrostatic operated by tor minerals at ipoh (malaysia), by dhrangadhra chemical29/06/2017 According to “PilotScale Demonstration of Ilmenite Processing Technology,” the peerreviewed report of this study, “The mineral ilmenite is an irontitanium oxide (FeTiO3) which is locally concentrated within small oxidebearing ultramafic intrusions (OUI) A New Generation of Mining Shown in Ilmenite Processing 14/12/2016 Ilmenite Processing Technology MPI Rutile Technology Exploration Results Ilmenite Permit EP57130 Exploration SANOFEX Project Overview; Waihi Exploration Review; FAQ; Contact Us; Carbon Zero Minerals; Menu Market Data Ilmenite Processing 14 Dec 2016 Ilmenite Processing Technology Featured Super User; font size decrease font size increase Ilmenite Processing Technology sanofex

Ilmenite To Iron Ore Processing Technology

The current paper thus aims to review the minerals processing technology of ilmenite by flotation together with some basic information about ilmenite It is hoped that a systematic knowledge about ilmenite upgrading can be built herein and recommendations can be made to guide future studies in the area of ilmenite minerals processing 2PilotScale Demonstration of Ilmenite Processing Technology PilotScale Demonstration of Ilmenite Processing Technology UMD NRRI iii chloride leaching and solvent extraction system parameters for the ilmenite concentrate The test program focused on the leach efficiency and extraction efficiency of the target elements iron and titaniumAs a leading global manufacturer ilmenite processing technology in zimbabwe18/07/2013 The potential applications of thermal plasma processing technology cover a wide range of activities such as the extraction of metals and the refining/alloying of metals/alloys/minerals This review describes the current status of ilmenite processing using thermal plasma technology A comprehensive analysis of available scientific and technical Thermal plasma processing of ilmenite: a review: Mineral

ilmenite beneficiation technology

14/06/2012 PilotScale Demonstration of Ilmenite Processing Technology) products from Minnesota ilmenite using beneficiation combined with Canadian Titanium Limited's (CTL) proprietary hydrometallurgical processing technology The project was conducted in collaboration with partial owner of the CTL technology: Process Research Ortech (PRO) An Ilmenite Processing Technology Duluth Laboratories Administration 5013 Miller Trunk Highway Duluth, Minnesota 55811 The mineral ilmenite is an irontitanium oxide (FeTiO3) which is concentrated within small $1642M USD to produce a >99% pure TiO2 powder product from mining 05 Mtpa crude ore PilotScale Demonstration of Ilmenite Processing PilotScale ilmenite to iron ore processing technologytitanium processing titanium processing, the extraction of titanium from its ores and the preparation of titanium alloys or compounds for use in various products Titanium (Ti) is a soft, ductile, silvery gray metal with a melting point of 1,675 °C (3,047 °F) Owing to the formation on its surface of an oxide film that is relatively inert titanium processing Technology, Methods, Facts

ilmenite processing technology lettierapercavalliit

The Application of New SLon Magnetic Separation Technology in Ilmenite Processing SLon Magnetic Separator Limited is the inventor and promoter of Wet High Intensity Magnetic Separator (WHIMS) In the past 30 years, the technical team led by Dr XiongDahe has always taken the development of magnetoelectricity mineral processing technology as

- iron ore bellas trituradoras

- la maquina chancadoras de asfalto

- trituradora trituradora de mesa de acero inoxidable

- equipo de proceso minero

- alogo trituradora de piedra

- Precio piedra trituradora Colombia

- venta de chancadora de piedra en peru

- motor electri chancadora pequea

- aplastamiento mecanismo de la trituradora de rodillos

- detalles de 40 toneladas por hora planta de trituración

- maquina chancadora de piedras mpras

- venta de trituradora de oro en Paraguay

- tifones Revestimientos De Molinos De Bolas

- molino de crudo para cemento

- alta capacidad molino de martillos trituradora

- rodillos de goma para molino de bola

- trituradora de piedra especificación de la máquina

- especificación técnica de molino de bolas explicativo por proveedor indio

- aleman fabricante de la maquina trituradora de piedra

- waste recycling crushers

- mini equipos de molienda molino de

- máquina de molino trapezoidal en monterrey venta

- disenos trituradora de piedra portatiles

- screening equipment for crushed stone

- trituracion de procesamiento o de mineral

- carbón de chancado y planta de cribado

- trituración tipo de agregado de plantas

- representante de pulverizadores yamaho en argentina

- bola equipo de molino cantera se agitoacute a la venta

- molino para la goma de tara