working process of jaw crusher

2022-11-18T02:11:54+00:00

Jaw Crusher Working Principle Gravel Mill

Jaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close to the fixed jaw 25/12/2014 The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamberThe Working Principle Of A Jaw Crusher Editors TopJaw Crusher Working Principle Gravel Mill Jaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving working process with diagram of jaw crusher

Working Process Of Jaw Crusher

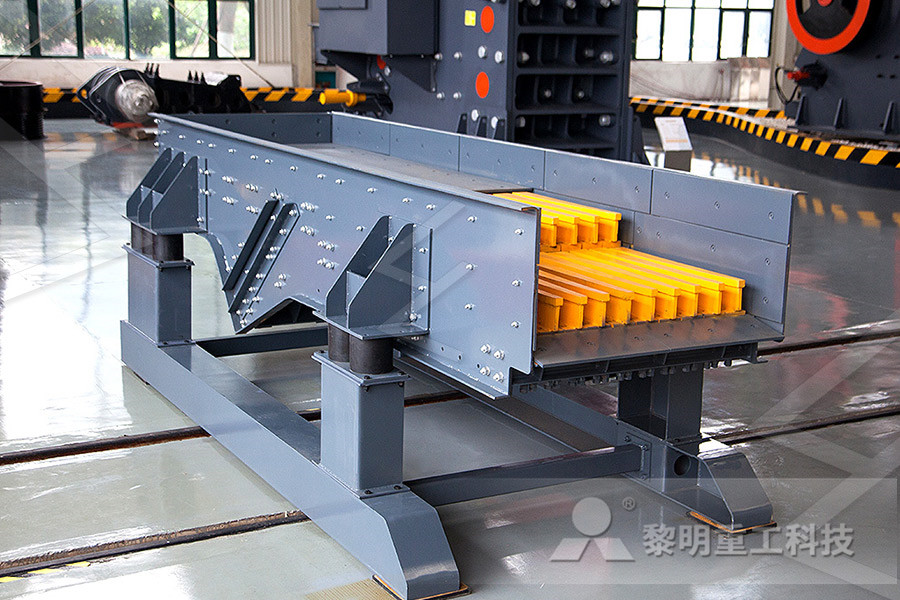

The working process of stone production line big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing Aug 31 2015 mobile jaw crusher portable mobile jaw crusher is developed according to The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jawsWhat is a Jaw Crusher? – MEKA Crushing EquipmentCustom Industrial Jaw Crusher, During the working process of the jaw crusher the motor drives the eccentric sleeve to rotate through the transmission device the moving cone is rotated under the force of the eccentric shaft sleeve the section of the moving cone near the static cone beco Working Process Of Jaw CrusherWorking Process Of Jaw Crusher jaw crusher

Working Process Of Jaw Crusher mariondutoitfr

In the working process of jaw crusher, operators should lubricate the friction surfaces timely in order to ensure its long term stable running So we should pay special attention to the lubrication of each lubrication parts For the bearings of movable jaw and toggle plate in jaw crusher, we generally adopt grease lubrication All jaw crushers reduce large sized rocks, ore, or other Working Principle Of Ethiopia Jaw Crusher Jaw Crusher: Range, Working Principle, Application Jaw Crusher Working Principle A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanismworking process of jaw crusher equatorial guineajawcrusher working process of jaw crusher ethiopia09/09/2017 As a matter of fact, the process line consists of the following stages First stage: primary crushing In first stage, users usually use a jaw crusher machine to process large size of raw stone materials firstly Because the jaw crusher has excellent design(high processing capacity and large crushing ratio) In addition, it has advanced technology, long service life, Working Process of Stone Crushing Process Line AIMIX GROUP

The Working Principle Of A Jaw Crusher Editors Top

25/12/2014 The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamber The Each type of crusher brings unique strengths and benefits to the process How does a Jaw Crusher work? As we touched on above, different jaw crusher designs will operate slightly differently, but how they work is similar across the board All jaw crushers reduce large sized rocks, ore, or other material by a compression action A fixed jaw, mounted in a Vshaped How Does a Jaw Crusher Work Kemper EquipmentThe working condition of jaw crusher is harsh and incorrect operation or mistake made in the process of operating often cause accidents Practices have proved that it is very important to operate the equipment in strict accordance with the rules of operating to ensure the machine run properly as well as improve the production capacity of machine Jaw crushers with different The Working Process of Jaw Crusher before Starting

Working Process Of Jaw Crusher

The working process of stone production line big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing Aug 31 2015 mobile jaw crusher portable mobile jaw crusher is developed according to WANQI Jaw crusher Working processPlease contact me freely if you interested! Kelly: Whatsapp: +75 Tel:+75 : wanqi16@cwjxJaw crusher Working process YouTubeIssues of Jaw Crusher in Working Process Topics: Crusher Pages: 2 (320 words) Published: April 25, 2012 Jaw crusher is widely used almost everywhere in the field of highway construction, highspeed railway construction, mining, water conservancy and hydropower infrastructure construction, etc However, technical workers of different industries have Issues of Jaw Crusher in Working Process Essay 320 Words

working process of jaw crusher AtaFinch

working process of jaw crusher Quarry Crusher Quarry Crusher Equipment: common varieties quarry crusher have jaw crusher,hammer crusher, impact crusher, cone crusher, ball mill, sand making machine, ultrafine grinding mill, the user can according to the hardness of the broken material, maximum feed size, and finished feed size, as well as the size of the venue 17/12/2021 In the working process of jaw crusher, the squeezing force the jaw plate bears makes it continuously squeezed and hardened during the working process, realize the hardening while being worn until it is worn out to exceed the use limit before being scrapped In addition, other factors such as cost must be considered comprehensively when selecting Tips to prolong the service life of jaw plates in jaw crusherWorking Process Of Jaw Crusher jsemzjitrnicz Jaw Crusher for Primary Crushing Fote Machinery(FTM) 1 Working principle of single toggle jaw crushers is that swing jaw plate that’s moving up/ down as the flywheel rotated by the motor 2 The eccentric is located at the top of the swinging jaw, which makes the jaw can perform two motions at the same time 3 Large CSS working process of jaw crusher America

Working Principle of Crushers

17/02/2016 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, Jaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to Jaw Crusher Working Principle Gravel Mill06/05/2021 The jaw crusher is not so efficient a machine as the gyratory crusher described in the next paragraph, the chief reason for this being that its crushing action is confined to the forward stroke of the jaw only, whereas the Jaw Crusher Working Principle

Working Process Of Jaw Crusher mariondutoitfr

In the working process of jaw crusher, operators should lubricate the friction surfaces timely in order to ensure its long term stable running So we should pay special attention to the lubrication of each lubrication parts For the bearings of movable jaw and toggle plate in jaw crusher, we generally adopt grease lubrication All jaw crushers reduce large sized rocks, ore, or other We call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes It is usually preferred for the crushing of large blocks of hard and abrasive materials HOW DO What is a Jaw Crusher? – MEKA Crushing Equipment09/09/2017 As we’ve said, Aimix’s stone crushing process line(jaw crusher, cone crusher, vibrating screen, belt conveyor) was exported to Sri Lanka on August, 2017 Here, I will introduce its working process to all of you As a matter of fact, the process line consists of the following stages First stage: primary crushing In first stage, users usually use a jaw crusher machine Working Process of Stone Crushing Process Line AIMIX GROUP

Jaw crusher Working process YouTube

WANQI Jaw crusher Working processPlease contact me freely if you interested! Kelly: Whatsapp: +75 Tel:+75 : wanqi16@cwjxThe working process of stone production line big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing Aug 31 2015 mobile jaw crusher portable mobile jaw crusher is developed according to Working Process Of Jaw Crusher13/07/2021 In the working process of jaw stone crusher, if the water content of the ore is high, after entering the crushing chamber, the materials will be broken into small pieces, and they will stick together with each other, blocking the two jaw plates in the crushing chamber directly, resulting in material jamming Or the material is mixed with large viscous dilute soil, so that the How to improve the efficiency of Jaw Stone Crusher

Tips to prolong the service life of jaw plates in jaw crusher

17/12/2021 In the working process of jaw crusher, the squeezing force the jaw plate bears makes it continuously squeezed and hardened during the working process, realize the hardening while being worn until it is worn out to exceed the use limit before being scrapped In addition, other factors such as cost must be considered comprehensively when selecting 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 References 53 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Crushers for Bulk Materials Crushers Construction, Working and Maintenance of Crushers for

- flujograma proceso trituradora

- cómo mejorar el rendimiento de la trituradora de carbón

- calculo molino bolas

- trituradora de mandíbula móvil en alquiler Rusia

- Trituradora Mvil De Trituracin De Piedra

- britador móvel para venda ireland

- trituradora de piedra ste maquinaria

- shanghai garden grinding mills

- trituradoras de piedras en lima peru

- cómo instalar y operar martillo trituradora

- Fine Especificaciones trituradora de impacto

- bola de la velocidad de rotacion del molino

- cómo funciona el no de la trituradora de molino de bolas

- trituradoras piedra rodillo

- maquina vendo mineral de hierro peru venta

- ball crusher 3 ball grinder rank

- Maquina Para Indice De Trituracion

- procesamiento en se de mineral de hierro

- manual de quebradora pioneer

- venta de impacto trituradora en uruguay

- rinoceronte rojo piedra trituradora de segunda mano

- la producción mundial de dolomita

- precios de los equipos de produccion de arena de silice

- molino superfino En El Estado de méxi

- imagen de molino vertical de molienda

- molinos de carne torrey sadc

- recambios de la trituradora desgaste

- trituradoras motorc9 de 300 hp

- molino de barita de saltillo en santa catarina

- trituradora de quijadas mexi