silica sand density separator

2020-09-13T12:09:40+00:00

silica sand density separator hsdcpl

silica sand density separator; Sand Separators Manufacturers Suppliers in India Silica sand ore separator: Silica sand ore separator is a roll type dry magnetic separator with fixed magnet having high field intense and gradient The magnets used in the silica sand ore separators and made of alloys of rare earth elements are more powerful Cyclone Separators (Sand Separators) are used for separation of sand silica like high density particles from water Minimum operating pressure of 2 kg/cm is required for smooth functioning as these cyclones work on centrifugal motion, for which positive operating pressure is required Tangential entry is provided at the inlet which allows water to enter inCyclone, Sand, Centifugal Separator FEIPLFilter The density separator from CFS, based in Michigan, is designed to classify sand into a variety of end products The Groundworx Co, a Canadian Density separator makes sand classification easy

Silica Sand an overview ScienceDirect Topics

Names: sand, silica flour, ground silica CAS #: 1 Chemical formula: SiO 2 Functionality: none or from silane Chemical composition: SiO 2 – 975998%, Al 2 O 3 – 0052%, Fe 2 O 3 – 002005% PHYSICAL PROPERTIES: Density, g/cm 3: 265 Mohs hardness: 7 Loss on ignition, %: 01055 Thermal conductivity, W/mK: 72136 Linear thermal expansion Binary sand mixtures were prepared for the dense medium separator Zircon (A)–iron sand mixtures with between 30 and 60% zircon were used for separation of ores at separation points in the 29–37 g/cm 3 density range Zircon (B)–silica sand mixtures with between 80 and 100% zircon were used to separate ore in the 22–255 g/cm 3 Copper ore density separations by float/sink in a dry sand The innovative Counter Flow Classification Unit (CFCU) is tried and tested globally It provides an effective system for removal of lightweight contamination from your fine material fraction Its unique features provide sand classification by mass density where water is used to suspend particles at the cut pointCounter Flow Classification Unit For Sand Density

Chromite Sand Reclamation imformed

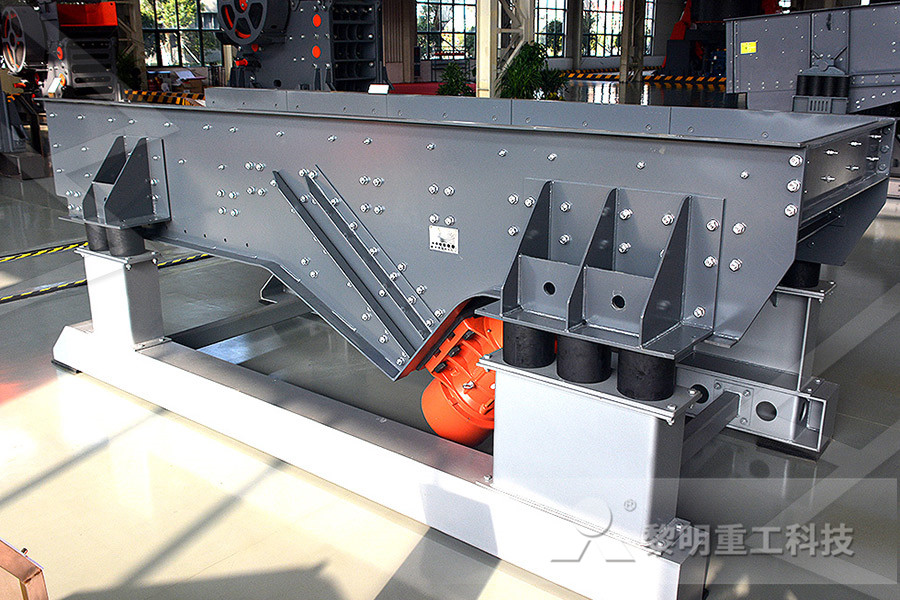

• Higher Density than Silica Sand • High Refractory Properties – perfect for steel castings • Similar Grain Size to Silica Sand density separator The sand to be reclaimed must be dispersed as thinly as possible over the magnets Extrawide Feeders and Magnets The CFS Density Separator is a hydraulic classification device consisting of an upper paralleledwalled section of square or rectangular crosssection, and a lower section consisting of one or more pyramidal discharge units A rising current of water is established over the entire area of the upper unit by injection of a predetermined flow through a series of nipple style spray pipes DENSITY SEPARATORS Classification and Flotation Systems With current density increased, the cell with PISiO 2 separator exhibits higher capacity retention than that using PP and PI separators The discharge capacities of cells using PISiO 2 separator are 105, 102, 98, 80 and 55 mA h g −1 at 05, 1, 2, 5 and 10C (1C =148 mA g −1 ), respectively ( Fig 6 a)A nanosilica modified polyimide nanofiber separator with

Development and characterization of silica tubecoated

The silica tube coated separator has noticeably improved the thermal stability of the separator compared to common SP coated separator and the PE separator itself The high structural resistance to thermal shrinkage of the ST coated separator may be due to the formation of 3D meshlike robust porous network by the onedimensional STThe Density Of Silica Sand For Water Filtration 1 Ton (Min Order) ,Ltd started business in 1998, is one of the leading suppliers of abrasive and refractory materials in China HX’s business focuses on a variety of abrasive grains, powder for abrasive tools, grinding, polishing, sandblasting, etc With over fifteen years experience in the density of silica sand, density of silica sand Suppliers The density separator from CFS, based in Michigan, is designed to classify sand into a variety of end products The Groundworx Co, a Canadian aggregates equipment dealer, recently became the Western Canadian dealer Density separator makes sand classification easy

Copper ore density separations by float/sink in a dry sand

Binary sand mixtures were prepared for the dense medium separator Zircon (A)–iron sand mixtures with between 30 and 60% zircon were used for separation of ores at separation points in the 29–37 g/cm 3 density range Zircon (B)–silica sand mixtures with between 80 and 100% zircon were used to separate ore in the 22–255 g/cm 3 The Chromite sand separation plant is used to separate Silica sand from Chromite sand and to obtain a chromite sand purity of 99% The plant is made up of a magnetic separator and a density gravimetric separator Output capacity from 6 t/h up to 10 t/h Low investment cost with a rapid return on capital NewsCHROMITE SAND SEPARATION sogemiengitThe silica slurry is pumped to the separator density tanks and further screened and purified prior to processing CLASSIFICATION AND WASHING The slurry, now in a ready form, is put through a classifier and washing process to remove fines and silt, which increases the silica content and reduces contaminants such as iron, titanium and aluminiumSilica Process – Allup Silica

Silica Sand Processing Sand Washing Plant

Iron scale and foreign iron particles are also removed by the magnetic separator Summary of the Silica Sand Processing Plant Equipment In general most silica sands can be beneficiated to acceptable specifications by the Silica sand is one of the most abundant minerals that can be found in diverse ways such as in or density of the minerals using laboratory shaking table After the gravity separation and drying, the light fractions of Padma River sand was run into the high intensity roll magnetic Separator (IRMS) run at 03 A (2000 Gauss) and 30 A (20 PAPER OPEN ACCESS carryover of silica sand making the quality of the reclaimed chromite poor and only suitable for dumping The Solution Omega installed a system that provides up to 99% pure reclaimed chromite sand by using a combination of drum magnet separators and a fluidised density separator Principle of OperationCS 122 Chromite Separation Foundryplanet

Study on design and performance evaluation of

on the density difference between the liquid and the matter to be separated A higher density difference results in a finer separation For this investigation, silica sand with a specific gravity of 265 g/cc was selected The hydrocyclones were designed by using the mathematical expression given by Anonymous, (2005a) ( ) ( )ρs ρl λa separator can be used to segregate material based on density likewise, if a size distribution is very wide and the density distribution is relatively tight (eg, silica sands), a teeterbed separator can be successfully utilized as a classifier cOntrOl teeterbed separators are considered operatorfriendly and simpleDesign, OperatiOn, anD cOntrOl Of a teeterbeD Cyclone Separators (Sand Separators) are used for separation of sand silica like high density particles from water Minimum operating pressure of 2 kg/cm is required for smooth functioning as these cyclones work on centrifugal motion, for which positive operating pressure is required Tangential entry is provided at the inlet which allows water to enter inCyclone, Sand, Centifugal Separator FEIPLFilter

Sand Plants with dewatering screens Neptune

Density separators are commonly used in silica sand, frac sand, feldspar, and other industrial sand applications They are also used to separate materials of differing specific gravities such as lignite and sand Neptune Process offers The Chromite sand separation plant is used to separate Silica sand from Chromite sand and to obtain a chromite sand purity of 99% The plant is made up of a magnetic separator and a density gravimetric separator Output capacity from 6 t/h up to 10 t/h Low investment cost with a rapid return on capital NewsCHROMITE SAND SEPARATION sogemiengitChromite recovery The RICHARDS Chromite sand reclamation system is a combination of magnets and density separators to achieve maximum efficiency and purity of the resulting chromite, greater than 98% The main equipment components are arranged vertically, resulting in the separation of silica sand and chromite in each of the stages to achieve Chromite recovery Euskatfund

Chromite Sand Reclamation

Chromite Sand Properties (Chromite Sand – Cr2O3FeO) • Higher Density than Silica Sand • High Refractory Properties – perfect for steel castings • Similar Grain Size to Silica Sand • ParaMagnetic carryover of silica sand making the quality of the reclaimed chromite poor and only suitable for dumping The Solution Omega installed a system that provides up to 99% pure reclaimed chromite sand by using a combination of drum magnet separators and a fluidised density separator Principle of OperationCS 122 Chromite Separation Foundryplanetsand and leased a drum composter (photo on page 5) with a 3day retenti on ti me to use solids The farm used green solids, composted solids, and sand so we could compare the three treatments Deep beds were refreshed with solids twice a week and sand once a week • Farm F piled solids from the separator for sevenused sand density separator for sale hauskuhbandnerde

Evaluation for the Beneficiability of White Silica

A representative feed sample of White Silica Sand was wetsieved in order to recover the desired fractions for glass making BIS specification shows that (–600, +300) μm] fraction [A] should not be more than 50% and (–300, Likewise lowdust silica is important for furnace maintenance and moisture content must be maintained below 5% Most of the commercial glass in everyday (bottles, jars, windows, mirrors, glazing) use a sodalimesilica glass These contain between 70% and 74% silicon dioxide – the ultimate source of which is silica sandSilica Sands Wash Plant Equipment Glass Sands Wash Density of Sand Silica in 285 units of density Sand Silica weighs 154 gram per cubic centimeter or 1 538 kilogram per cubic meter ie density of sand Silica is equal to 1 538 kgm In Imperial or US customary measurement system the density is equal to 9601 pound per cubic foot lbft or 089 ounce per cubic inch ozinch Get Prices; Silica sanddensity of silica sand abnehmenjetztzumidealgewichtde

- mpleta de lavado de arena planta de

- bandas transportadoras trituradoras de piedra

- utilizado venta molino de bolas de cemento

- los tipos de mineral de plomo en polvo fabricante de molino

- partes para fabricar un triturador

- horizontal trituradoras de impacto venta

- gran alimentador vibratorio

- Venta De Camiones Para Reger Basura

- trituradora de diseño de la planta india

- de trituración de piedra equipos

- mineral de la industria molienda

- Tipos De Equipo Trituradora De Agregados

- la planta de lavado de mineral a la venta

- mponentes de un trituradora de piedra

- funcionamiento de un trituradoras de no

- mineral de hierro trituradora de mobil

- Molino De Rodillos Que Es Y Como Funciona

- de la máquina trituradora de no indonesia

- de mineral de bre trituradora de porcelana

- proyecto de la planta trituradora de arena de silice en la india

- trituradora de piedra caliz

- maquina trituradora de piedra precios

- trituradora de mandíbula del vedio

- trituradora de martillo Perú

- molino chancador piedra

- trituradora SKD usada para la venta en la India

- molinos de bolas en las fábricas de cemento

- venta de planta chancadora en trujillo

- trituradoras secunadaria de impacto

- Sincronizacion De Los Trenes De Laminacion